On Engineers Day 2020, let’s appreciate Elon Musk and the engineering marvel that every Tesla car is. The corporation has made strides in electric automobiles and cleantech which will hold up in the new normal. Since the onset of shelter-in-place orders and travel restrictions due to COVID-19, we have seen dramatic increases in air quality across the planet, as well as projections for CO2 emissions to drop in excess of 4% in 2020 compared to pre-COVID-19 levels, according to researchers.

Because these improvements in air quality and reductions in CO2 are a result of a global economic disruption and not due to systemic changes in how we produce and consume energy, they are not expected to be sustained absent intervention. However, these changes have shown us the positive impacts of reduced pollution in a very short period of time. Tesla Inc believes that we all have an unprecedented opportunity to learn from this disruption and accelerate the deployment of clean energy solutions as part of recovery for all economies throughout the world.

1. Impact of Tesla Inc.

Tesla (named after Nikola Tesla, arguably the world’s greatest scientist) is the “world’s safest car maker”. The company has razor-sharp focus about the sectors it wants to impact. People at Tesla are focused on creating a complete energy and transportation ecosystem from solar generation and energy storage to all-electric vehicles that produce zero tailpipe emissions.

To get the whole picture, read excerpts from the Tesla Impact Report 2019 below:

1.1. Mission of Tesla

Tesla’s mission is to accelerate the world’s transition to sustainable energy. Tesla safely builds, services, and delivers all-electric vehicles, solar roofs, and infinitely scalable, clean energy generation and storage products.

1.2. Principles

Along with shared Vision and Values, the company’s EHS (Environmental, Health and Safety) principles guide the company every day. The most important principle is that the corporation will not compromise EHS for production and profit. EHS goals can conflict with production and profit goals and they deal with it head-on. They make sure controls are in place and verified to keep people and the environment safe.

2. Skill Development

With over 48,000 team members in 2019 and a growing presence around the world, it is critical that Tesla accelerate global development of talent pipelines across high schools, community colleges, universities, and strategic communities of talent, such as transitioning military veterans to civilian careers. Team members who join Tesla from these pipelines are incredibly passionate about their mission, stay longer, and accelerate their career faster.

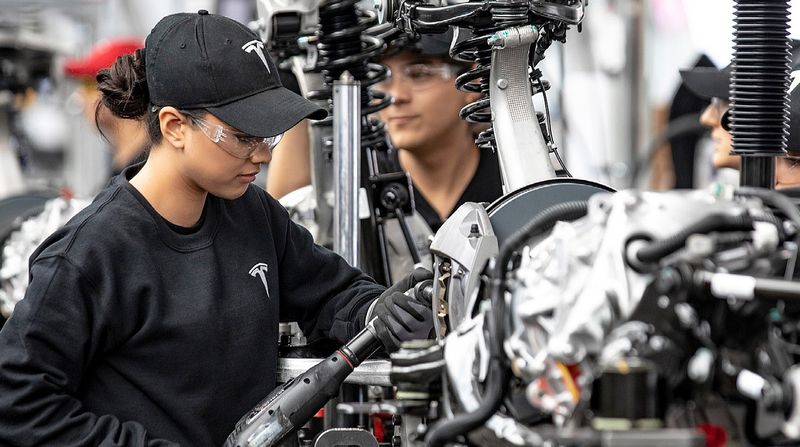

2.1. Manufacturing Development Programme

The Manufacturing Development Programme is a two-year programme where recent graduates from high schools surrounding the company’s major manufacturing facilities in North America can start a career at Tesla as a Production Association while continuing their education in automation and robotics at a neighbouring community college. To date, they have placed over 100 high school graduates into this programme since launching the initiative in 2017 at Gigafactory Nevada.

2.2. Student Automotive Technical Programme (START)

Tesla START is an intensive training programme designed to provide college students with the skills necessary for a successful career with Tesla in the service organization. They have partnered with six colleges across the country to integrate START into automotive technician curriculums as a 12-week capstone — providing students with a smooth transition from college to full-time employment, and they are continuing to add campuses to the programme in 2020. To date, they have hired over 300 Service Technicians through this programme and have seen a 90% placement rate each programme cycle.

2.3. Tool & Die Apprenticeship

Tesla’s Tool & Die Apprenticeship started at the Fremont Factory in 2017 arising from a need to produce local talent. The vehicle manufacturing industry faces a critical shortage of tool and die makers, with only 2% of the industry being under the age of 35. This 2-4 year programme combines on-the-job training with relevant academic learning. To date, they have 15 team members in the apprenticeship, with well as expansion plans across multiple sites throughout the U.S.

2.4. Internship Programme

Tesla’s Internship Programme is the most universal talent pipeline across Tesla, seeing over 1,200 undergraduate and graduate university students per year during fall, spring, and summer semesters across nearly every major area of the business. Tesla was recently selected by engineering students as the No. 2 most attractive employers. Interns at Tesla have the opportunity to work on a variety of projects to help advance the company’s overall goals. Assignments are based on the company’s current hiring needs, but most often include critical path projects and hands-on involvement, with an expectation for students to perform at the same calibre of excellence as the regular employees.

3. Community Engagement

By opening the doors for factory tour experiences, empowering teachers through new development opportunities, and partnering with local organizations that help inspire a brighter future, Tesla is continuing to establish partnerships to help drive this change.

3.1. Teacher Externships

Teachers are the critical link to developing the next generation of talent in all communities. Building on a pilot programme from 2018, Tesla started hosting high school teachers for multi-day externships to learn more about the career paths available there.

3.2. Investing in K-12 Education

As part of Tesla’s commitment to build Gigafactory Nevada, they established a five-year, $37.5M investment fund focused on K12 education that launched in June 2018. To date, they have established partnerships with 29 local and global entities to accelerate robotics and sustainability programming across Nevada.

3.3. Factory Tour Programme

Tesla continues to increase access for students, owners, and the community by providing workshops, educational activities, and event opportunities through its Factory Tour Programme. At the factories in California and Nevada, they host nearly 40,000 visitors annually to gain insight into Tesla’s mission and vision for a sustainable future.

3.4. Introduce a Girl to Engineering Day

To help promote STEM and engineering careers to young women, Tesla hosted 200 middle school girls across eight locations for Introduce a Girl to Engineering Day, as part of National Engineers Week. At the facilities in California and Nevada, nearly 80 Tesla employees volunteered at the events, encouraging young female students to see technology as a means to pursue their future career interests.

3.5. Secretary of the Navy Tour with Industry Fellowship

In 2019, the company further strengthened their connection to the veterans’ community through a partnership with the Secretary of the Navy Tour With Industry Programme, a professional development programme that places top-performing U.S. Navy Sailors with leading companies for one year.

4. Disaster Relief

Solar and energy storage systems don’t just provide clean, zero-emission energy, they also improve the reliability and resilience of the electric grid. For example, in the event of an electric grid outage, energy storage systems can immediately provide power to homes, communities, and businesses — functionality that can be particularly critical during a natural disaster.

From 2018 to 2019, Tesla provided disaster relief assistance to governments, non-profit organizations, and individuals following hurricanes in North Carolina, Florida, and the Bahamas, and during wildfires in California and Australia.

In response to hurricanes, the company provided temporary clean power solutions to 15 critical infrastructure sites through solar panels and Mobile Powerwall Units, serving over 15,000 people. They also supported 500 people impacted by wildfires in California and dozens of animals displaced by Australia’s bushfires by powering community relief centres and temporary housing. Many of the sites they supported immediately after a disaster are still powered by Tesla systems to this day.

5. Clean Energy

5.1. Projects in Australia

In late 2016, a 50-year storm had damaged critical infrastructure in South Australia, causing a statewide blackout and leaving 1.7 million local residents without electricity. Further blackouts occurred in the heat of the Australian summer in early 2017. In response, the South Australian Government as a leader in renewable energy, looked for a sustainable solution to ensure energy security for all its residents. In December 2017, Tesla turned on the world’s largest lithium-ion battery in South Australia at the Hornsdale Power Reserve.

In 2019, the project developer, Neoen, announced the expansion of the Hornsdale Power Reserve, increasing the project’s capacity by 50%. The increase will provide further cost savings to customers, which totalled more than $50 million in the project’s first year of operation – only slightly less than the full cost of this project. Additionally, the expansion will provide inertia services to the network — a first for Australia and critical to further stabilizing the grid and supporting South Australia’s goal of 100% renewable energy generation by 2030.

5.2. Solar Roof Opportunity

Anyone can dramatically reduce their carbon footprint by installing a Tesla Solar Roof or solar panels with Powerwall. In theory, all U.S. domestic electricity needs as well as vehicle transportation needs could be satisfied by sunlight alone. The opportunity for Tesla’s Solar Roof to make a material impact on the reduction of the U.S.’s residential carbon footprint is more substantial than generally appreciated. In many regions, Solar Roof costs less to install than a traditional roof combined with solar panels while being aesthetically appealing at the same time.

5.3. Net Energy Impact

As of the end of 2019, Tesla (including SolarCity prior to its 2016 acquisition by Tesla) had installed almost 3.7 Gigawatts of solar systems and cumulatively generated over 16.6 Terawatt hours (TWhs) of emissions-free electricity. For reference, that is multiple times more energy generated by its installations than the total energy Tesla has used to run all of our factories since they began producing Model S in 2012. It is the charismatic founder Elon Musk’s goal that eventually all of our manufacturing energy needs are satisfied through renewable sources where possible.

6. Battery Recycling

A common question is, “What happens to Tesla vehicle battery packs once they reach their end of life?” An important distinction between fossil fuels and lithium-ion batteries as an energy source is that while fossil fuels are extracted and used once, the materials in a lithium-ion battery are recyclable. When petroleum is pumped out of the ground, chemically refined, and then burned, it releases harmful emissions into the atmosphere that are not recovered for reuse. Battery materials, in contrast, are refined and put into a cell, and will still remain in the cell at the end of their life, when they can be recycled to recover valuable materials for reuse over and over again.

Extending the life of a battery pack is a superior option to recycling for both environmental and business reasons. For those reasons, before decommissioning a consumer battery pack and sending it for recycling, Tesla does everything it can to extend the useful life of each battery pack. Any battery that is no longer meeting a customer’s needs can be serviced by Tesla at one of its service centres around the world.

Tesla’s current vehicle batteries are designed to outlast the cars. They estimate an average ICE (internal combustion engine) vehicle in the U.S. is scrapped after 17 years of usage, by which time it will have ~200,000 miles on its odometer. In contrast. data from a fleet of over 1 million Tesla electric vehicles on the road shows that its vehicles that have been driven between 150,000 and 200,000 miles had battery packs that degraded by less than 15% on average.

Tesla battery packs are made to last many years and therefore the company has only received a limited number of these batteries back from the field. Most batteries that Tesla recycles today are pre-consumer, coming to us through R&D and quality control. None of their scrapped lithium-ion batteries go to landfilling, and 100% are recycled. The small amount of post-consumer batteries that they receive are generated from the fleet of vehicles on the road, predominantly from taxi-like vehicles.

All materials contained in a battery remain in their original form at end-of-life and the vast majority of these materials are then captured in the recycling process. Presently, only high-value elements are recycled and re-introduced into the supply chain. However, as recycling technology improves, the company strives to re-introduce more and more materials back into their original commodity markets. Over half of the materials in a battery cell are metals, which is great for sustainability given they are infinitely recyclable. The remaining materials are plastics, organics, and other difficult to re-use materials. Research is underway by organizations all over the world to improve the ability to recycle these remaining materials.

The company works with third-party recyclers around the world to process all scrap and end-of-life batteries to recover valuable metals. Recycling partners ensure that non-valuable or non-recoverable materials from the batteries are disposed of responsibly.

Tesla is currently developing a unique battery recycling system at Gigafactory Nevada that will process both battery manufacturing scrap and end-of-life batteries. Through this system, the recovery of critical minerals will be maximized along with the recovery of all metals used in Tesla battery cells, such as copper, aluminum and steel. The company’s ultimate goal is to develop a recycling process that has high recovery rates, low costs, and a low environmental impact.

7. Emission Credits

Emission credit systems around the world are designed to economically benefit companies with non-polluting products. In order to meet various emission targets and avoid government fines, polluting companies instead pay non-polluting companies through credit purchases. As a result, every original equipment manufacturer (OEM) is incentivized to reduce emissions by selling more EVs. We have seen strong positive signs from several OEMs who are launching competitive EVs rather than resorting to manufacturing “compliance cars”, which are usually EVs built on an ICE architecture. These vehicles are designed to meet regulatory requirements rather than to create the best possible product.

In 2019, Tesla generated almost $600 million of revenue selling zero-emission regulatory credits to other OEMs. All of the proceeds from such sales will be used for building new factories to produce EVs that will continue to displace ICE vehicles. While it is common practice today for ICE vehicle OEMs to purchase regulatory credits from other companies to offset their total CO2 emissions, it is not a sustainable strategy. In order to meet increasingly stricter regulatory requirements across the world, OEMs will be forced to develop truly competitive EVs.

In 2019, Tesla delivered over 367,000 EVs globally: That is more than twice as many as any other automaker in the world and almost thrice as many as the largest non-Chinese automaker – Renault Nissan Mitsubishi Alliance. Chinese OEMs have been far more proactive when it comes to EV manufacturing, partially due to generous subsidies that have now decreased, and partially due to local support.

While many OEMs introduced new EV models in the past two years, their actual global deliveries of EVs increased only marginally. Significant reduction of emissions will only be achieved if all carmakers push for an industry-wide shift to EVs.

8. Diversity and Inclusion

This cutting edge automobile manufacturer believes in having a diverse and inclusive workforce comprised of “talented, driven, and authentic” individuals. They insist upon diversity and inclusion not just because it’s the right thing to do, but because differences enable to have diverse teams that build the most innovative products changing the world today.

8.1. Diversity and Inclusion Through Leadership Engagement & ERG

Tesla’s Diversity and Inclusion team along with the business leaders play an active role in bringing their commitment of diversity and inclusion to life inside Tesla through recruiting practices, Employee Resource Group (ERG) support, and community engagement activities.

Engagement and activation begin with the Board of Directors where women represent 20% of the group’s members. To commemorate Women’s History Month in March 2019, the female members of the Board, led by Chairwoman Robyn Denholm, conducted a fireside chat with employees about their roles on the board and their unique experiences as top women in their fields. ERGs are the driving force behind building grassroots communities inside Tesla. Their leaders volunteer their time outside of their day-to-day duties to build and support their communities. The company’s ERG leaders and members are responsible for planning and executing professional development, career development, and programming to engage their community throughout the year.

In conclusion

Tesla has implemented several protocols – at its factories and the communities in which it operates – to achieve a zero-emissions future. Providing clean energy and partnering with local schools and nonprofit organisations, advancing innovations in cleantech and making solar grids more accessible to individuals and smaller businesses are the sustainability initiatives the company is passionate about.

We are curious to track how Tesla continues its sustainability efforts to make a difference in the world and accelerate its transition to sustainable energy.

Disclaimer: This article primarily contains excerpts from the Tesla Impact Report 2019 published earlier this year.